ALUMINIUM REPAIR RODS

- Pack of 5 Rods

Rods are Australian made

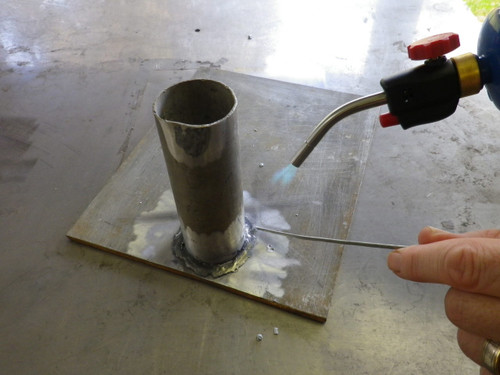

Ultra bond allows you to make fast easy repairs or even fabricate in Aluminium and other non ferrous metals, using just a BBQ gas bottle or a handyman gas torch.

ULTRA BOND aluminium repair rod is a strong, easily applied weld or braze for repairing or fabricating aluminium and other non-ferrous metals. It is also compatible with Zinc, Copper, Brass, Bronze, Die Cast, Pot Metals, Pewter and other non-ferrous metals. It is not compatible with ferrous metals (metals with an iron content). If in doubt, if a magnet sticks to the metal, ULTRA BOND won't.

ULTRA BOND'S most valuable use, however, is for repairing broken aluminium or fabricating aluminium pieces. This is because the rod is applied at a low enough temperature (380 degrees c) to avoid melting, warping or crystallizing the base metal. The rod has a higher tensile strength than aluminium. ULTRA BOND actually penetrates aluminium chemically while in the molten state to form a "fusion weld" that is stronger than the aluminium being welded. In addition, ULTRA BOND is easily applied "in house" with a small torch. It is much less expensive than conventional aluminium welding, welding contractors or part replacement.

- ALL YOU NEED TO USE ULTRA BOND IS a heat source such as an LPG gas bottle or Barbecue gas bottle, a torch and something to clean the metal with such as a stainless steel wire brush and with a little practice following our step by step instructions you will be able to quickly and easily make repairs in aluminium and other non ferrous metals

- STEP 1 CLEANINGAluminium to be welded should be thoroughly cleaned to remove all paints, oils, oxidation and other contaminants. A Stainless steel brush ,A brass wire brush or aluminium oxide sandpaper may be used to clean the metal. Also, a clean file or grinder work well if followed by stainless steel brushing. If the aluminium is anodized, the anodized coating must be filed, ground or sanded off. Paint may be removed with paint thinner or blistered with a torch when brushed. Always brush the metal until shiny to remove all oxidation. Metal will be oxidized some under flame, so occasional brushing during a lengthy heating is useful. Always file cast aluminium and die cast as a stainless steel brush won't clean case aluminium adequately. If the aluminium is oily, heat the metal and wash with vinegar or muriatic acid, rinse with more vinegar. Don't rinse with water. No need to wipe dry. .

- STEP 2 TINNING After the metal to be welded is clean, it should be heated with a torch. If possible, this should be done without playing the torch on the immediate weld area, and with a neutral or carbonizing flame. When the metal is hot enough to melt ULTRA BOND to a shiny wet appearance the areas to be welded should be tinned by scratching or "scrubbing" the rod on the metal. This breaks the surface tension of the puddle and allows the molten rod to break down oxidation that may be present on the surface of the metal. If you suspect that the puddle is not penetrating through to the metal, scratch the metal through the molten puddle with a stainless steel wire or a sharp knife or tool. Another variation on this strategy is to brush the puddle away while it is still hot, then tin the surface a second time.

- When repairing a crack, tin both sides of the crack. When joining two pieces of metal,tin both pieces. When repairing a hole or leaking boat trivet, tin the area around the hole.

- STEP 3 WELDINGWhen all appropriate areas have been tinned, brush rod tip from tinned area to tinned area to join the tinned surfaces with a continuous puddle or bead. ULTRA BOND has good surface tension in the puddle and will easily span small gaps, holes and cracks. ULTRA BOND penetrates the surface of aluminium, forming an extra strong bond, and efficient joints are formed by bridging. Since ULTRA BOND is stronger than aluminium, the joints will be stronger than the surrounding area. Let the weld air cool. DO NOT QUENCH.

Note: We have Stainless steel and Brass wire brushes available separately if you need them for cleaning the metal before the repair

Want to see more? watch ultra bond in action on the video on our website

Customer review 2019

New message from: aussie#######c##r (574)

Hey team,

I just wanted to thank you so much for saving me out of this mess. your product is fantastic!

I'm self employed and the 2010 Hyundai I load T/Diesel began running bad after 185K's on the odometer, I is direct injected and has a tendency to build up carbon/soot in emission, Inter-cooler-EGR valve-inlet manifold-Etc was clogged and inter-cooler had leaks. I purchased four different branded cheap rods on E bay and they caused even more damage to the inter-cooler. vehicle has been out of action for 3 weeks or so. It was at the point where customers had to complain to my clients for the delays in the work. thank god your product arrived this morning. it was so easy to braze.

Copyright Robson's Tool king 2015 all rights reserved, unauthorized copying and or reproduction in part or full strictly prohibited.

- Why buy from tool king?

- When Buying from tool king you can buy with confidence.

- We have over 38 years experience selling hand tools, so its safe to say that we really know our stuff.

- Unlike many online retailers we do actually have traditional street front retail stores, so we aren't going to disappear on you, Plus it also makes us easy to contact should you have any questions.

- Tool-king is 100% AUSTRALIAN family owned with over 3 generations working in the business

- We Employ Australians, when you buy a product from tool king rather than overseas you are helping to keep Australians employed.

- All our friendly staff are Australian so they speak fluent English, and that makes us easier to speak to.

- And Remember that when you Buy from an Australian Business you are keeping Australians Employed and you are doing your part to help our economy and keeping jobs here in rural areas for future generations of Australians.

43 Reviews

-

Aluminium brazing rods

I needed to repair some aluminium blocks that I can’t replace. These brazing rods worked great! I have tried other brands but they melt at too high a temp, these ones melt as stated and give a good result. I was able to machine my repair back to spec. They work great if you follow the video tutorial.

-

Ultra Bond aluminium brasing

Fantastic product, first attempt worked brilliant. Saved me 10 times the amount of product if professional welded and still have spare rods for another repair. Cannot recommend this product more highly.

-

Aluminium soldering/brazing

I restore old cars, often replicating missing /worn/broken die cast alloy parts.Works very well, able to fabricate these small components in aluminium, instead of brass, steel etc.....

-

exel

does what is add

-

aluminiun welding rods

easy to use item is as described

-

Ultra Bond Al Repair rods

Makes it possible anyone with minimum welding skills and equipment to do a range of aluminium repairs. Strongly recommend

-

Ultra bond low temp aluminium rods

Used these to fix a few holes and cracks on a tinny. Seemed to work ok.

-

Ultra bond rods

As per video great product

-

Ultrabond Aluminium Rods

Excellent product. Great for amateurs